Productos

- Equipos de Control de sólidos

- Triple Deck Shale Shaker

- Zaranda de movimiento lineal

- Desgasificador de vacío

- Limpiador del fango

- Desarenador

- Desarenador

- Decantando la centrifugadora

- Sludge Vacuum Pump

- Secador de corte vertical

- Zaranda de secado

- Mezclador del fango del jet

- Agitador de lodo

- Bomba centrífuga

- Bomba del esquileo

- Bomba Slurry sumergible

- Arma del fango

- Separador de Gas del fango

- Dispositivo de encendido de fuego

- Bomba de tornillo

- Tanque de hidratación

- Tanque de lodo

- Elevated Oil Tank

- Diesel Tank/Oil Tank

- Sala de centro Control de motores

- Transportador de tornillo

- Offshore Mud Skip Container

- Sistema de Control de sólidos

- Piezas de repuesto

- Drilling Rig

Contacto

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China  +86-29-89305761

+86-29-89305761 +86-29-89305769

+86-29-89305769

Casos

-

3000hp Drilling Rig Circulation System for 9000m U...

3000hp Drilling Rig Circulation System for 9000m Ultra Deep Drilling Proj...

-

2000hp Drilling Rig Mud Tank System for Saudi Arab...

2000hp Drilling Rig Mud Tank System for Saudi Arabia As earl...

Noticias de tecnología

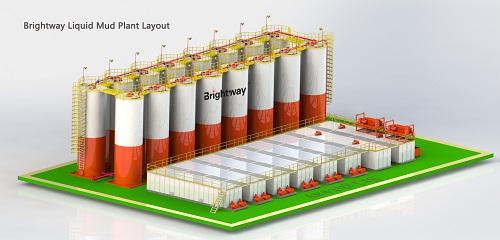

Design & Build of Liquid Mud Plant

2022-04-06

The main design and build of the drilling liquid mud plant include storage tanks, which is mainly used for the preparation, recycling, processing and storage of oil and natural gas drilling water-based drilling fluids, and it is convenient to transfer in or out, and provide base support services for each drilling operation point. Mud tanks meet the requirements of convenient disassembly, flexible placement, and standard container size for easy transportation. The total storage capacity is about 1000 square meters.

Overview of the design of liquid mud plant

(1) Drilling liquid mud plant, the main equipment is pump

skid-mounted assembly, mud mixing tank, storage tank, mainly used for the

configuration, recovery and storage of drilling fluid, and provides shore for

drilling operations and basic support services. The liquid mud plant design

meets the requirements of convenient disassembly and assembly, flexible

placement, and standard container size for easy transportation;

(2) The effective storage capacity of the liquid mud plant is 1000

m³ and the loading

capacity is 120 m³/hr. The

construction includes 1 mixing pump skid (1 for water-based), 1 slurry mixing

tank (1 for water-based) and 10 mud storage tanks; each tank has an effective

volume of 100m³ and size

12200×3020×2800mm;

(3) Applicable explosion-proof devices;

(4) Wind resistance.

This method of centralized treatment of liquid

mud plant can greatly reduce the risk of environmental impact assessment and

construction costs. In the future, the construction of centralized liquid mud

plants will gradually become popular in oilfield drilling projects. Brightway designs

and builds liquid mud plants to provide you with more useful equipment and

consultation related to oilfield drilling. Welcome to inquire us by emailing us

at brightway@bwwell.com.

Anterior :Drilling Liquid Mud Plant Shipped to Customer

Próxima :300 Pieces of Shaker Screens Shipped to an Azerbaijan Customer