Productos

- Equipos de Control de sólidos

- Triple Deck Shale Shaker

- Zaranda de movimiento lineal

- Desgasificador de vacío

- Limpiador del fango

- Desarenador

- Desarenador

- Decantando la centrifugadora

- Sludge Vacuum Pump

- Secador de corte vertical

- Zaranda de secado

- Mezclador del fango del jet

- Agitador de lodo

- Bomba centrífuga

- Bomba del esquileo

- Bomba Slurry sumergible

- Arma del fango

- Separador de Gas del fango

- Dispositivo de encendido de fuego

- Bomba de tornillo

- Tanque de hidratación

- Tanque de lodo

- Elevated Oil Tank

- Diesel Tank/Oil Tank

- Sala de centro Control de motores

- Transportador de tornillo

- Offshore Mud Skip Container

- Sistema de Control de sólidos

- Piezas de repuesto

- Drilling Rig

Contacto

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China  +86-29-89305761

+86-29-89305761 +86-29-89305769

+86-29-89305769

Casos

-

3000hp Drilling Rig Circulation System for 9000m U...

3000hp Drilling Rig Circulation System for 9000m Ultra Deep Drilling Proj...

-

2000hp Drilling Rig Mud Tank System for Saudi Arab...

2000hp Drilling Rig Mud Tank System for Saudi Arabia As earl...

Noticias de tecnología

Brightway Decanter Centrifuge and Its Application to Desulfurization

2016-06-14

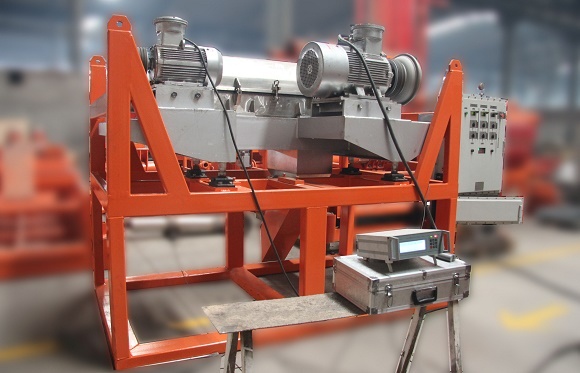

After technical and commercial exchanges for 2 months, Brightway designed and manufactured one set BWLW High-speed Desulfurization Decanter Centrifuge for Russia customer. Recently, The Decanter Centrifuge has tested successfully at the factory. It will send to Cho Ming Oilfield of Russia and will be used in the fields of Desulfurization.

Desulfurization Decanter Centrifuge tested successfully

Desulfurization Decanter Centrifuge is used the principle of difference solid-Liquid specific density and depend on centrifugal force. The solid-phase is subsided under the action of centrifugal force and then can achieve solid - liquid separation. The process of feeding and separation is continuous, closed and automatic. The centrifugal machines applied to recycling a variety of suspended sulfur in sulfur foam and it can be run at low temperature and has the characteristics of low sulfur wastage, less power consumption, good cealing.

Anterior :Analysis on the Treatment Technology of Oil-based Mud

Próxima :Brightway Oily Sludge Treatment Systems Sent to A Domestic Oilfield